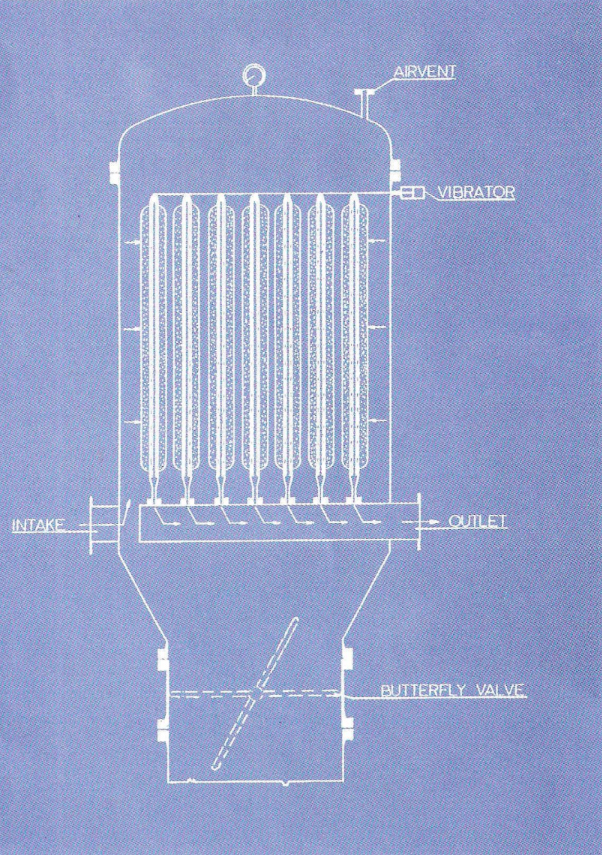

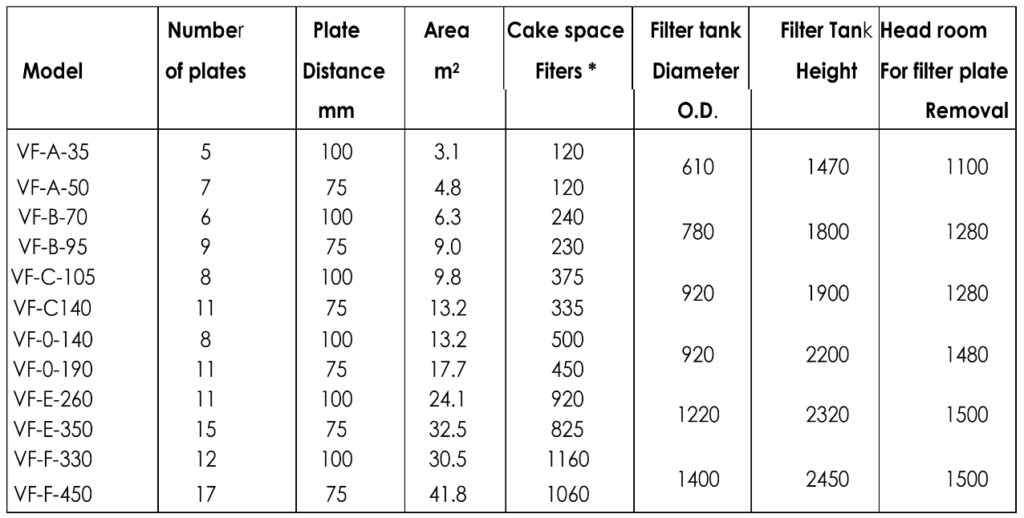

The Vertical Plate Filter (VF) is a pressure filter and consists of a vertical tank with vertically positioned filter plates. VF filter plates filter on both sides, offering a large filtration area in a relative small vessel. The VF filter can be used for a variety of applications.

VF filters are suitable for wet or dry cake discharge.

Wet cake discharge filter models are cleaned by built-in spray pipes. The slurry is discharged through a large bottom drain. In Dry Cake Discharge filter models, the filter is equipped with a pneumatic vibrator. The cake is

discharged either through a hydraulic operated quick opening tank bottom or a butterfly valve. The filter cake can be dried by compressed air, inert gas or steam before the cake is discharged by the vibrator. Vertical Plate Filters can be utilized for manual, semi-automatic or fully automatic operation.

An ideal filter for crude oil, micelle as well as bleaching earth filtrations with dry cake discharge. Also suitable for nickel recovery.

For the recovery of smaller and larger amounts of catalyst. Removal of catalyst as dry cake or slurry. Popular in hydrogen peroxide, hydrogenation processes.

For the clarification of liquids after decolonization, purification or deodorization processes.

Vertical Plate Filters are used in a variety of chemical processes, like amines used in gas scrubbing, detergents, liquid polymers, fertilizers, water filtrations and many more.

Vertical Plate filters can be used for polishing of liquids before storage or further processing. The large cake volume assures long cycles, against the lowest operational costs.

Tanks and all wet table parts are available in several grades of stainless steels.

Standard tank construction accommodates 4 bar working pressure. Higher pressures are available on request. Allowable pressure difference across the filter plates 3.5 bar.

Optional equipment includes heating or cooling jackets, segment clamp bolted or hydraulic operated quick opening covers, Pneumatic vibrator, top mounted sprays.

The operation of a Vertical Pressure Leaf Filter is labour intensive and requires a complex manipulation of valves so present day installations are in most cases fully automated.

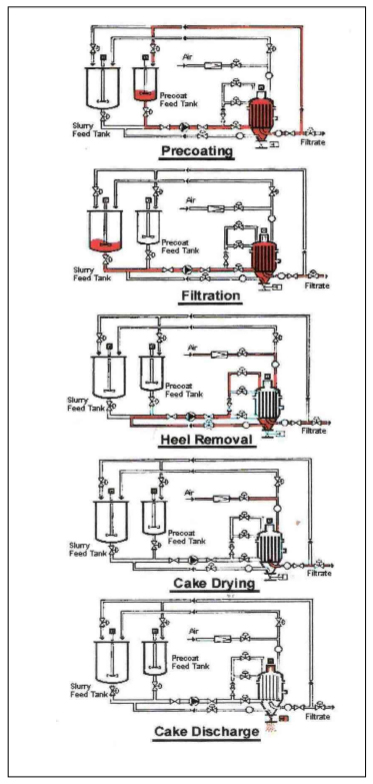

The precoating stage is done only in the following cases:

When the contaminants are gelatinous and sticky the precoat layer forms a barrier that avoids cloth blinding. Likewise the interface between the precoat and the cloth departs readily so the cake discharges leaving a clean cloth.

When a clear filtrate is required immediately after the filtration cycle commences otherwise recirculation must be employed until a clear filtrate is obtained.

Once the precoating stage is completed the process slurry is pumped into the filter, the forming cake is retained on the leaves and the filtrate flows to further processing.

When the solids are fine and slow to filter a body-aid is added to the feed slurry in order to enhance cake permeability. However, it should be kept in mind that the addition of body-aid increases the solids concentration in the feed so it occupies additional volume between the leaves and increases the amount of cake for disposal.

Likewise, for all those applications when the cake is the product, precoat and filter-aid may not be used since they mix and discharge together with the cake.

Once the filtration cycle is completed air or gas is blown into the vessel and the slurry heel that surrounds the leaves is pushed and displaced downwards until it reaches the lowest part of the leaf stack. At this point the remaining heel slurry is evacuated back to the feed tank by a special dip pipe that is located at the very bottom of the vessel so that the vessel is empty from slurry.

The air then continues to pass through the cake until the captive moisture is reduced to a minimum and the cake is in practical terms considered to be dry.

At this point the air pressure is released, the cake outlet is opened and the leaf stack is vibrated to discharge the cake. The cake outlet opening must be interlocked with a pressure sensor to avoid opening under pressure.

The Vertical Pressure Leaf Filter requires attention on a regular basis to safety devices and automation features that accompany modern filters.

The space above the filter should have a hoisting device and sufficient headroom to lift each leaf and move it horizontally to a location adjacent to the filter tank. It is recommended to have a special rig that will hold the leaf for maintenance. Space must also be allocated for the cover which may be either hinged or removed.

The major components that require attention are:

* The indicated cake capacity is based on a max. Cake thickness of respectively 26 and 38 mm, at plate distance of 75 and 100 mm.

+91 98924 94910

patil@everesteng.com

W-113, MIDC, Phase-II, Dombivali, Thane

We aim to build the company, revitalise & nurture our products as brands in the all time growing market.

In 2008 the company entered into a growth phase with the purpose of achieving an annual, organic growth rate of 15-20%. The company means to keep pace with the changing scenario in the manufacturing technology, to understand what the customer requires in terms of up gradation in technology and develop products accordingly. At the same time the Company will continue to improve its product range so that its products will always be ready to face the competition.