This filter is used for solid and liquid separation which is aided with the application of vacuum and cake squeezing by mechanical means.

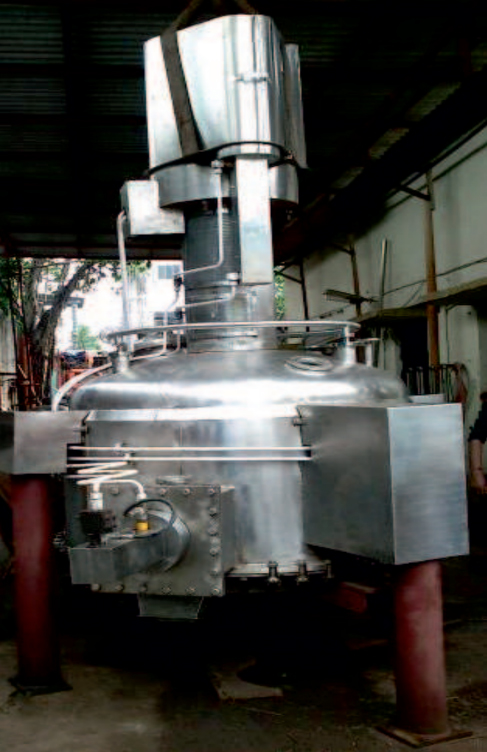

Agitated Nutsche Filter consists of a cylindrical vessel with a welded dished end on the top and a flat bottom or dishend.

The process is totally enclosed, hygienic and safe which make it ideal for processing toxic and hazardous material human contact.

This equipment can be operated under pressure or in vacuum or in combination of both.

Cake discharge is done with the help of stirrer. Provision for spraying wash liquor is in build in the equipment.

The Filter has a special type of agitator with scrapper, mounted with lantern supports on the top of dished end. The agitator is capable of performing the following operations:-

1) Solids in suspension are not allowed to quickly settle down on the filtering medium and there by causing a blinding effect for filtrate. After considerable quantity of filtrate passes through, stirrer is raised and filtration by capillary action continues.

2) During final stages of cake formation, cake starts cracking and vacuum below the cake gets short circuited through the cake thereby stopping the final stages of liquid extraction from the cake. When the cake starts cracking, stirrer is rotated in anti – clockwise direction also known as smoothening direction and the cracks are closed by simultaneously bringing down the stirrer, so that it plasters the surface of the cake and closes the cracks. It can even slightly press the cake and squeeze out some of the liquid.

3) After cake formation is complete, very good washing can be achieved by adding wash liquid and re – slurring the cake, resulting in contact of every particle of the cake with wash liquor and then repeating the filtering operation till cake is formed again. Washing and reslurring can be done as many times as necessary to achieve good cake, or good filtrate without much residue left in the cake.

4) During the Drying cycle, the wet cake is manipulated with the agitator to transfer heat and the vacuum flashes the solvent out of the wet cake. A dust catcher can provided to arrest any dry powder that is entrained in the vacuum stream.

5) Finally by rotating the stirrer in the ‘Discharge Direction’ and bringing it down , cake can be mechanically discharged by opening the discharge door.

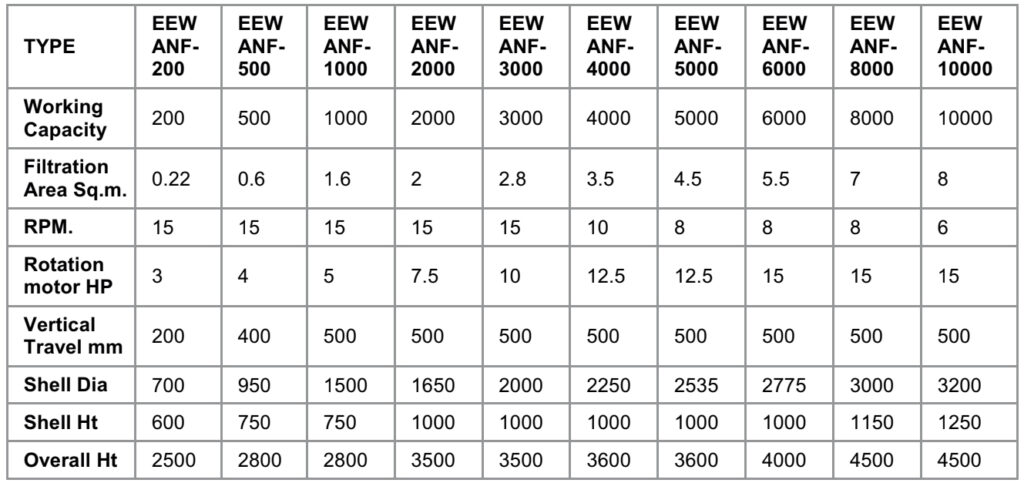

NOTE: We reserved the right to change the design & dimensions of equipment without notice

+91 98924 94910

patil@everesteng.com

W-113, MIDC, Phase-II, Dombivali, Thane

We aim to build the company, revitalise & nurture our products as brands in the all time growing market.

In 2008 the company entered into a growth phase with the purpose of achieving an annual, organic growth rate of 15-20%. The company means to keep pace with the changing scenario in the manufacturing technology, to understand what the customer requires in terms of up gradation in technology and develop products accordingly. At the same time the Company will continue to improve its product range so that its products will always be ready to face the competition.